EARLY PRODUCTION FACILITY

Sparklet Designs Horizontal, Vertical Separators for Production and Well Testing, to separate and measures the Oil, Gas and Water produced.

Designed as per Customer Specifications:-- Phase

- 2 Phase & 3 Phase

- 3 KG / CM2 TO 200 KG / CM2

Nominal Capacity

For Production:-- Gas Upto – 5 MMSCMD

- Liquid Upto – 100000 BBL / DAY

- Gas Upto – 100 MMSCFD

- Liquid Upto – 20000 BBL / DAY

- Process Design

- Mechanical Designs

- Complete Drawing Package with use of Cad, Solid Works

- Skids designed to DNV 2.7 or equivalent EN standard

- Skid mounted first stage three phase production separator

- Indirect water bath heater

- Skid mounted second stage three phase production separator

- Stripping column

- Knock out drum

- Pump skid

- Heat exchanger

- EPF facility range from minimum 5k to 15k maximum.

- All flow, pressure, level and temperature are monitored and controlled by electronic transmitters locally and remote also.

- Sparklet stripping column consist of Random packing as N-Type nutter rings and N2 Gas as stripper.

- Highly safe environment is provided by giving highly improved Hazardous gas analyzers and fire detection system.

- Indirect water bath heater is designed to handle viscous oil form 4 cP to 35 cP

- Water sprinkle arrangement provided on skid for fire safety.

- All interconnecting pipe line provided by Sparklet.

- All skids combined with superior drain arrangement to have clean skids

HIGH PRESSURE

MEDIUM PRESSURE

LOW PRESSURE

HP Inline Separator

HIPPS

CRUDE STABILIZATION SYSTEMS

STABILISATION removes Hydrogen Sulphide before the Oil is stored. Hydrogen Sulphide is commonly found in crude oil and when exposed to water it forms H2 So 4. This acid can corrode the process equipments and pipeline.

The stabilization process does two jobs- It sweetens the sour crude.

- It reduces Vapour Pressure making the crude safe for shipment in tankers.

As the crude works its way down through the trays near the bottom the oil is channeled to a reboiler that heats it.

The crude Stabilization systems comes with the following packages- STABILIZER COLUMN

- SIDE REBOILER

- BOTTOM REBOILER

- WATER DECANTER.

The equipments can be with or without cladding depending on the process requirements. The columns are designed to handle plant capacity of 50,000 bbl/day

STABILIZER COLUMN

STABILIZER SIDE REBOILER

STABILIZER BOTTOM REBOILER

Connections : Standardized sizes for easy assembly. Additional thread and surface protection for clean installation.

Tubesheet : Stainless steel straight or U-tubes in a carbon steel shell. Available in a variety of diameters and lengths, Shell and tube heat exchanger transfer large amounts of heat at a relatively lower cost.

Gaskets : High quality compressed fibres (reusable).

Head: Standard cast-iron or steel head for heavy duty services (also available as a spare part).

Mounting : Saddles attached with standard units for quick & easy mounting.

Baffles : Punched baffles with minimum clearances between tubes assures correct fluid flow and minimized bypass.

Shell : Welded shell protected with high quality paint for corrosion resistance.

Tube Bundle : Stainless steel tubes allow for strong, durable performance over a wide range of applications. Unique tube bundle layout minimizes buildup problems at the edges and optimizes media flow in the unit.

Crude Export Air Cooler

Shell And Tube Exchanger

LP Crude Preheater

HP Preheater

MP Preheater

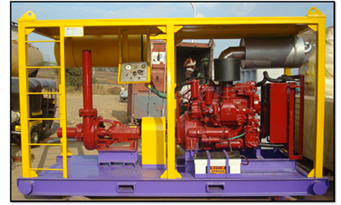

SPARKLET is a p manufacturer of pump skid systems across multiple industry sectors. Pump skid systems come complete with PLC automation and touch-screen controls, and are ready to move fluid or product when arriving on site. Our engineers work closely with your team to design a custom pump skid system using the latest 3D modeling software. Accuracy and safety are at the forefront of our engineering, and our team will ensure your pump skids meet or exceed any technical, OSHA, or government regulations. Packaged pump skids are a custom solution for your fluid handling needs. Bring us your ideas or specifications and our in-house mechanical and electrical engineers will help you find the best solution for your project. We have years of experience creating custom pump skids that are fully automated with PLC and touch-screen controls.

PERFORMANCE HEATER

- High level of instrument to monitor & control temperature from both shell & tube side.

- Special Expansion bellows arrangement.

- Size : 32” x 394”Fuel gas flow rate : 5332 Kg/Hr.

- Heat Duty : 22.21 MMBtu/Hr.

CRUDE PRE-HEATER

- Vessel type slug catcher

- Sufficiently large vessel to store

- Largest slug expected from upstream system

- Key equipment between outlets of pipeline processing equipment.

- Internal To be used

- Coalescer pack

- Inlet deflector

- Stilling baffle

- Vane pack

FUEL GAS SCRUBBER

HP SOUR GAS SCRUBBER (SMMSM)

LP GAS SCRUBBERS

- Dia : 24”

- Pressure : 14 bar

- Random Packing : N-type Nutter ring as interna

- Size : 29” x 8.2’

- Liquid : 3000 bpd.

- Gas : 3 mmscfd.

- Design Pressure : 100PSI.

BLACK POWDER GAS FILTERS

RICH AMINE FILTERS

LEAN AMINE FILTERS

Standardized sizes for easy assembly. Additional thread and surface protection for clean installation.

Fuel gas at skid battery limit, available at some pressure and temperature, is routed to the Knock Out Drum Vessel. Any free liquid contaminant is knocked off in the KOD prior to heating the fuel gas in the Pre-heater. Pre-heater ensures that temperature of fuel gas is kept above the hydrate temperature as the Pressure reduction valve at the downstream of pre-heater reduces the pressure. The pre-heater is an electric heater designed with the required number of coils. Temperature of fuel gas measured at inlet and outlet of heater. The heater coils are protected against high temperature, which when actuated, stops the heating of the coils.

The heated fuel gas is routed to Filter Vessel. The vessels are fitted with coalescing elements of high efficiency and which can remove particles of less than 0.3 microns. Smooth changeover of filter vessel is envisaged so as to ensure continuous supply of fuel gas to turbine. A high differential pressure across the filter due to clogging of the filter element would require changeover to the standby filter vessel.

The fuel gas at outlet of filter vessel is again heated in a super heater. This super heater is again an electric heater and is designed to heat the fuel gas to a temperature that is at least 50 deg F above the dew point of fuel gas. Temperature of fuel gas measured at inlet and outlet of heater, feeds to a temperature controller which in turn controls the heating in the heater. The heater coils are protected against high temperature, which when actuated, stops the heating of the coils.

The fuel gas at the outlet of super heater is again treated in dry filter vessel. The vessel is fitted with coalescing element of high efficiency and which can remove particles of less than 0.3 microns. A high differential pressure across the filter due to clogging of the filter element would require changeover to the standby filter vessel. Smooth changeover of filter vessel is envisaged so as to ensure continuous supply of fuel gas to turbine.

Second Stage Desalter

PRODUCTION MANIFOLDS

INLET MANIFOLDS

Technical Description- Design Pressure : 1315 Psi

- Working Temperature : 300 Deg F

- Main Header Piping : 12”

- Test Header Piping : 6”

ESD MANIFOLDS

Technical Description- Design Pressure : 1360 Psi

- Working Temperature : 200 Deg F

- Line Size : 6”

Air coolers are widely used in Oil & Gas, Steam House System, Hot Oil System and other major Systems and Industries. The main purpose of Air Coolers which uses Air as a cooling medium to reduce the temperature to desired limit. These are the most economical Items in Cooling area and reduce the Utility Cost. These Air Coolers are designed for high Pressure Temperature applications as desired. The Selection of the Tubes are as per the Process requirement to suit the Process Condition.